Made In Lavenham

Made in Lavenham

Tuesday, 29 September 2015

Tuesday, 24 February 2015

Friday, 6 June 2014

Current Sites (06/06/2014)...

On a day trip t Lavenham I managed to take these photos of two of the factory sites.

(The Mill entrance hasn't changed at all).

This is what The Station now looks like:

It was hard to see past the boards but it didn't seem as if there was anything left of the old factory.

These photos show the new houses that have been built on the site of Riverside Works:

Thursday, 3 April 2014

Perfume…

1940/50's VINTAGE PERFUME ENCHANTE BY EVETTE

MADE IN ENGLAND – 6 C.C.

Height of bottle: 2 inches

Description from Ebay:

“Two small bottles of perfume Charmant boxed but no cellophane, the box is a little bent, bottle measures just under 2 inches in height, just over 1 inch across, the other is unnamed and measures just over 2 inches in height and just under 1 and half inches across”.

Charmant No 23 miniature perfume.

Found on Ebay.

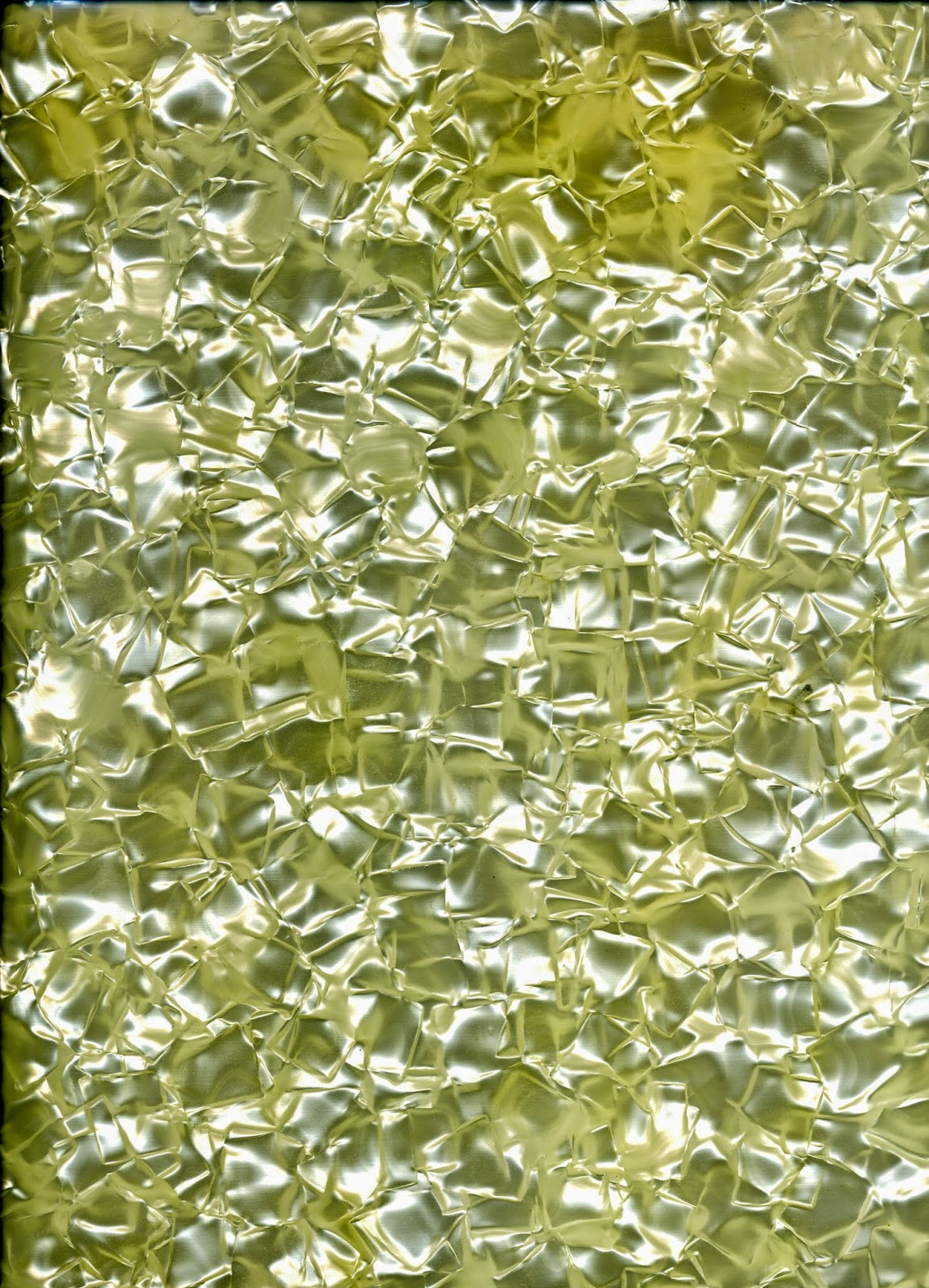

Mysterious Sheets of Plastic…

Someone sent me scans of two plastic sheets (4 ft x 2 ft) which were used in the factory in the 1970s / 80s, however they were unsure what they were used for. The scans are below (click to enlarge) and if you happen to know the answer then please let me know so that the mystery can be solved.

The following information was sent to me by an ex-worker on the theory of what the plastic sheets may have been used for:

“If these items of plastic sheeting were fairly bendy, they could have possibly been used on the vac formers to mould into inserts for top range boxed cosmetic sets to be assembled at the Riverside works. I do know that rolls of polypropylene were used on these machines, but it was often in white or black. Alternatively, they could also have been samples used by the in-house package design team. The brownish sheet looks a lot like the tortoiseshell effect plastic cases used for the boxed gift sets they used to assemble with eye shadows etc at Riverside. I think these cases were imported, in the end, from abroad ready to be filled with make-up”.

Other ex-workers have suggested they are something to do with cosmetic boxes.

I myself vaguely remember the pattern on the lighter plastic but cannot recall where I saw it….

Welwyn Garden City...

The Welwyn Garden City site was known as Barnet Combs where many items, including combs, were produced. The building was very close to the Shredded Wheat factory, Knorr Soups, Polycell (which occupied an old film studios) and a cigarette factory. Almost next door was Devices Ltd who manufactured the first heart pacemakers.

The R & D department was where they developed PVC bottle blowing techniques.

This all closed in about 1968 and all production was moved to Lavenham*.

(*Many thanks to an ex-worker who provided me with this information).

From another ex-worker, Brian Cook:

“When Barnet Combs was taken over by Holpak (a subsidiary of Unilever), they had a production factory built on the out skirts of Glemsford, not far from Lavenham. One of the main products was the Ski yoghurt pots, Fairy liquid bottles, Parazone bottles, Domestos bottles and injection moulded products. There was a small repair tool room, but if a major breakdown occurred then a toolmaker / toolmakers would be sent from here in Welwyn Garden City, often overnight stays,weekends too (production came first). The factory site was by the banks of the river Stour, on the Clare - Long Melford road, (the factory is no longer there).”

To read more quotes from Brain and to see some of his photos, please click this link:

Additional information:

From here: http://www.gracesguide.co.uk/E._R._Holloway

E. R. Holloway of Hyde Way, Welwyn Garden City, Herts. Telephone: Welwyn Garden 597. Cables: “Allkombs, Welwyn Garden City”

1947 British Industries Fair Advert for “Barnet” combs and slides – for reliability and durability. Manufacturers of the “Barnet” Series of Hair Combs, Hair Slides and Sundry Articles. Proprietors of Lustrac Plastics Limited, Manufacturers of “Lustrac” Cellulose Acetate and Vinyl Acetate Injection Moulding Powders. (Plastics Section – Earls Court, 1st Floor, Stand No. 790) [1]

1950 A substantial interest was acquired by Thomas Tilling.

The Holloway Group of Companies

In step with the growth of plastics, the Holloway Group continue to expand their range of products, made both here in Welwyn Garden City and at Glemsford in Suffolk.

Although Britain’s largest hair comb manufacturers, the Group have extended their activities to more and more other fields, from brushware to sunglasses, including plastic components and containers that serve other industries; and the subsidiary, “Lustrac Plastics,” makes raw material for both the Group and outside customers.

Local people, however, will be most familiar with “Barnet Comb Company” which is the Group’s manufacturing company with its main factory in Hyde Way, Welwyn Garden City.

E. R. Holloway’s Ltd. warehouses and offices operate in Bessemer Road. From here the Group products go all over Britain and the world; and despite the increasing size of the company the character of a family business is still preserved, under direction of Holloway brothers in active management.

The Group employ highly skilled tool makers and engineers, machine operators, finishers, assemblers and packers, beside other warehouse and administrative personnel.

Plastics by E. R.Holloway Ltd.

The association of the E. R. Holloway Ltd. group of companies with Welwyn Garden City dates from 1934 when they transferred from Southgate a small factory engaged in the finishing of vulcanite combs.

The story of the progress of E. R. Holloway Ltd. and their associated companies may not be remarkable, but it is typical of that of the many family businesses whose contribution to the prosperity of this country has been so invaluable. A limited company was formed in 1924 and offices were taken in the City of London, but not until 1931 was any manufacturing done, and then it was only the finishing, by processes that now seem crude and laborious, of vulcanite combs. From the time when this small factory of the Barnet Comb Company arrived in the Garden City the manufacturing side of the business began to go ahead until within a few years almost all the goods sold by E. R. Holloway Ltd. were the products of their own subsidiary.

In 1938 the warehouse and offices left the City for the more attractive and convenient site adjacent to the factory. Since then and indeed even before, the record has been one of constant experiment and innovation, and of almost equally constant growth. An injection moulding machine was installed in 1936 and the Barnet Comb Company produced commercially the first injection-moulded comb in this country.

Lustrac Plastics Ltd., a further subsidiary, was formed in 1943 for the manufacture of moulding powders. This in turn proved a success. Not only were its cellulose acetate powders wanted for the group’s own products, but a prosperous trade was built up with outside moulding firms. This company has now turned its attention to other materials besides celullose acetate and has extended its activities to include extrusion processes. It is thus able to meet the growing industrial demand for such articles as shaped rods and tubes.

The most recent addition to the group is Hydeway Ltd., a company started in 1949 for the production of welded plastic goods such as wallets, bags and purses. Again healthy progress can be reported.

For over thirty years now, the aim of the directors of this group has been to give a quality and a service second to none. The results speak for themselves. Since the end of the war, in spite of raw materials shortages and of increasing competition, the output of the group has increased by over 300 per cent in volume, and the increase by value has been even greater. Moreover, since a high proportion of its goods are sent overseas, the group has the satisfaction of knowing that it is making its contribution to the nation’s export drive.

Throughout its history good relationships have been maintained between management and employees and every attention is given to the improvement of working conditions. For several years now all employees after three months’ service participate in a profit-sharing scheme.

Barnet Combs c1938.

Excursions…

This photo was found on Flickr.

“Fred horrex with len Hebditches bedford on an excursion with holloways the ladies make up company from lavenham on an excursion to Wood Norton in 1970.”

Works excursions was something I hadn’t heard of during my time there,

so I was amazed to see this photo on Flickr.

Offices (Costing / Buying / Planning / Personnel / Sales / Bought / Wages)…

Many thanks to Andy Bowes for the following information:

“I was at Holloways between January 1986 and March 1988. I started in the Costing Office. It was a small office at the bottom of the stairs opposite the reception.

The cost accountant was John Lucas and I was the assistant cost accountant. My job mainly seemed to be answering the phone! I was also given a job of doing the sales sheets for Mr Holloway senior (Bertie) every day. I used to take a big stack of printouts and summarise them on one big sheet. We reported to the finance director Adrian Bridge, whose office was next door to ours.

At that time, the factory manager was Clive Bareham & the main engineer/maintenance guy was Paul Abbott.

In the Buying Office, the manager was Paul Pepper & the staff were Stella Soanes, Jackie Cullen, Beverley Cotter and Jeremy Rides.

The Planning Office was next door, managed by Bill Corsi. Ray Bradley was the production director.

Opposite Mr Bradleys office was Personnel, which was staffed by Joy Swancott and Astrid Day.

After about a year, I was moved to Sales Ledger Office, which was upstairs. We were managed by Jackie Warom and we had Brenda Hanks, Adele Christie, Helen ? and Christine Webber in the office. My job was mainly doing reconciliations of the Woolworths purchases (which could be up to about £3 million in one month). I also had to take the monthly cheque from Woolworths to London and pay it into Woolworth’s head office branch of Barclays so it would get transferred to Holloways account immediately.

Next to Sales ledger was the kitchen where Daphne ? & Peggy Clarke used to make the teas & coffees. On the other side of the Sales Ledger office was the Bought Ledger & Wages office, managed by Warren Mitchell. They used to pay the staff in cash and each Friday they used to come round with your wages & payslips in envelopes, which you had to sign for. You always hoped it would be before lunchtime so you could go to the pub!

There was also the design office managed by Jon Baxter and the exports office managed by Simon ?

There were a few other names I remember from upstairs – Chris Holloway, Jane Moorcroft, Donna Slater, Paula Long”.

From another ex-planning office worker: “Some of the people that I remember in the planning office were Dionne, Marie Farrow, Julie Waterhouse Biggins, Gary Howard and Bill.”

Here is some additional/further information from Andy:

“Walk through the main entrance to the Riverside works. Reception desk is on the right (Shirley was the receptionist in my day), the stairs are on the left. Further to the left was Adrian Bridge’s (Finance Director) office and next to that was the costing office where I started. We shared the same door.

More or less directly in front was the door out to the filling floor. Round to the right, past the reception was a corridor. On the left was the clocking in machine, Clive Bareham’s (Accountant then factory manager) office, a room with a printer in which printer the works order listings and such like and then personnel, which was home to Joy Swancott and Astrid Day. On the right of the corridor was the boardroom and Mr Bradley’s (Production Director?) office. At the end of the corridor was the planning office and you had to go through the planning office to the buying office.

Upstairs on the left was Bertie Holloway’s office and next to that his secretary Sue Bull. Turn right and there were 2 offices – 1 directly in front of you and one on the right. Not sure what these were but I remember Nicki Harvey sat in one, as did Jane Moorcroft and Donna Slater. The other one had Paula Long in it and at the end of it was Chris Holloway’s office.

Before you got to these 2 offices, you went left, through a double door and you had the kitchen to the left and sales ledger in front of you. I ended up there with Jackie Warren, Christine Webber, Adele Christie, Brenda Hanks and Helen……????. Next to sales ledger was bought ledger/wages office, managed by Warren Mitchell.

“I was at Holloways between January 1986 and March 1988. I started in the Costing Office. It was a small office at the bottom of the stairs opposite the reception.

The cost accountant was John Lucas and I was the assistant cost accountant. My job mainly seemed to be answering the phone! I was also given a job of doing the sales sheets for Mr Holloway senior (Bertie) every day. I used to take a big stack of printouts and summarise them on one big sheet. We reported to the finance director Adrian Bridge, whose office was next door to ours.

At that time, the factory manager was Clive Bareham & the main engineer/maintenance guy was Paul Abbott.

In the Buying Office, the manager was Paul Pepper & the staff were Stella Soanes, Jackie Cullen, Beverley Cotter and Jeremy Rides.

The Planning Office was next door, managed by Bill Corsi. Ray Bradley was the production director.

Opposite Mr Bradleys office was Personnel, which was staffed by Joy Swancott and Astrid Day.

After about a year, I was moved to Sales Ledger Office, which was upstairs. We were managed by Jackie Warom and we had Brenda Hanks, Adele Christie, Helen ? and Christine Webber in the office. My job was mainly doing reconciliations of the Woolworths purchases (which could be up to about £3 million in one month). I also had to take the monthly cheque from Woolworths to London and pay it into Woolworth’s head office branch of Barclays so it would get transferred to Holloways account immediately.

Next to Sales ledger was the kitchen where Daphne ? & Peggy Clarke used to make the teas & coffees. On the other side of the Sales Ledger office was the Bought Ledger & Wages office, managed by Warren Mitchell. They used to pay the staff in cash and each Friday they used to come round with your wages & payslips in envelopes, which you had to sign for. You always hoped it would be before lunchtime so you could go to the pub!

There was also the design office managed by Jon Baxter and the exports office managed by Simon ?

There were a few other names I remember from upstairs – Chris Holloway, Jane Moorcroft, Donna Slater, Paula Long”.

From another ex-planning office worker: “Some of the people that I remember in the planning office were Dionne, Marie Farrow, Julie Waterhouse Biggins, Gary Howard and Bill.”

Here is some additional/further information from Andy:

“Walk through the main entrance to the Riverside works. Reception desk is on the right (Shirley was the receptionist in my day), the stairs are on the left. Further to the left was Adrian Bridge’s (Finance Director) office and next to that was the costing office where I started. We shared the same door.

More or less directly in front was the door out to the filling floor. Round to the right, past the reception was a corridor. On the left was the clocking in machine, Clive Bareham’s (Accountant then factory manager) office, a room with a printer in which printer the works order listings and such like and then personnel, which was home to Joy Swancott and Astrid Day. On the right of the corridor was the boardroom and Mr Bradley’s (Production Director?) office. At the end of the corridor was the planning office and you had to go through the planning office to the buying office.

Upstairs on the left was Bertie Holloway’s office and next to that his secretary Sue Bull. Turn right and there were 2 offices – 1 directly in front of you and one on the right. Not sure what these were but I remember Nicki Harvey sat in one, as did Jane Moorcroft and Donna Slater. The other one had Paula Long in it and at the end of it was Chris Holloway’s office.

Before you got to these 2 offices, you went left, through a double door and you had the kitchen to the left and sales ledger in front of you. I ended up there with Jackie Warren, Christine Webber, Adele Christie, Brenda Hanks and Helen……????. Next to sales ledger was bought ledger/wages office, managed by Warren Mitchell.

To the right was the export office where Simon ??, Sharon ?? & Lisa Grainger worked. Round a bit to the left was the design office where John Baxter was in charge and Darren Guiheen worked. There were also some stairs down to the filling floor.

Out onto the filling floor, if you went right, you walked down to the goods in & stores where Brenda Long was in charge and also Damon Corbett & Rachel Zanoni worked. Through there was the canteen.

If you went past the goods in, you ended up at the powder room, or round to the right was the lipstick room and the lab.

Turning left on the filling floor took you down to the warehouse, Marks & Spencer’s, the old bath salts belt, the nail polish room and the mascara filling machine.

I remember Paul Abbott being the chief maintenance man, Ron Davies the factory manager, Mac the lorry driver, Olive Hollocks, Sharon Hollocks, Wally Byford, Joan Mayes…….”

New Scientist Magazine 18th June 1987…

Advertising...

Evette Leaflet 1963.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

1981 Display Stands.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

Advertising Posters.

Staff Magazine...

The New Bond..

I was completely unaware of a staff magazine while I was working at E. R. Holloway Limited, but have since been shown these images which were taken from various magazine issues…

I was completely unaware of a staff magazine while I was working at E. R. Holloway Limited, but have since been shown these images which were taken from various magazine issues…

August 1963.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

June 1967.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

December 1967.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

April 1968.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

April 1971.

Many thanks to www.woolworthsmuseum.co.uk for allowing me to use these images.

Newspaper Articles...

This write-up appeared in The Suffolk Free Press on Thursday June 4th 1964.

This write-up appeared in The Suffolk Free Press on Thursday February 6th 1969.

Here are two articles. One appeared in The Suffolk Free Press on Thursday March 31st 1977

and the other was in The East Anglian Daily Times on February 8th 1977.

This write-up appeared in The East Anglian Daily Times on April 10th 1979.

From the Suffolk Free Press, 8th March 1984 and The Sudbury Mercury 8th August 1993.

From the Suffolk Free Press 26th August and 2nd September 1993,

and The Sudbury Mercury September 3rd 1993.

The official opening of the new extensions.

Subscribe to:

Comments (Atom)